Understanding Power Distribution Systems

- Industrial IT Solution Pvt. ltd

- Oct 14, 2025

- 5 min read

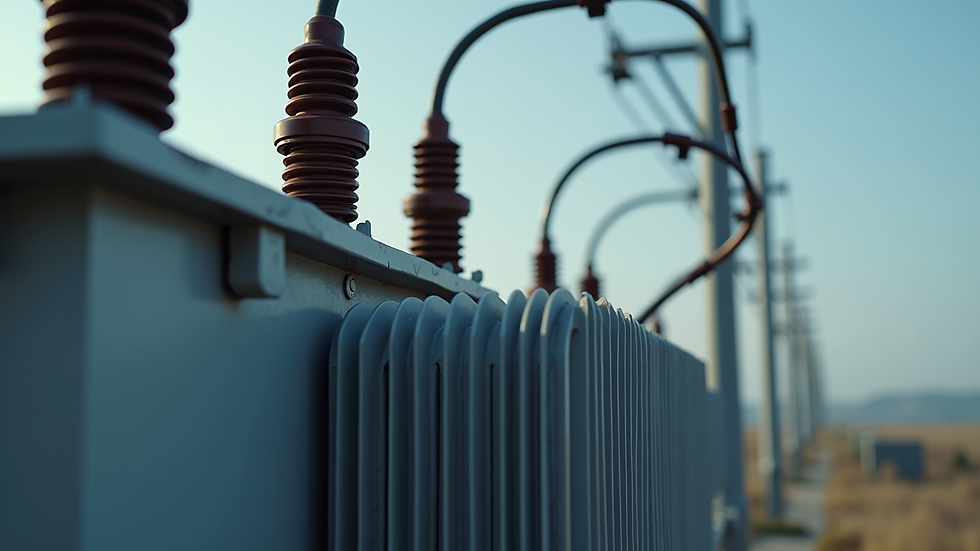

In today’s rapidly evolving industrial landscape, efficient and reliable energy management is not just a necessity but a strategic advantage. Energy distribution systems form the backbone of industrial operations, ensuring that power reaches every corner of a facility safely and efficiently. Whether you operate in power generation, sugar processing, cement manufacturing, metals and steel production, oil and gas, water utilities, pulp and paper, or emerging renewable sectors, understanding these systems is crucial for optimizing performance and sustainability.

Energy distribution systems are complex networks designed to deliver electrical energy from generation points to end-users. Their design, implementation, and maintenance directly impact operational efficiency, safety, and cost-effectiveness. In this article, I will walk you through the fundamentals of energy distribution systems, their components, and the latest trends shaping their future.

The Role of Energy Distribution Systems in Industrial Operations

Energy distribution systems are the arteries of any industrial facility. They transport electrical power from substations or generation units to machinery, lighting, control systems, and other electrical loads. The efficiency of these systems determines how well an industry can manage its energy consumption, reduce downtime, and maintain safety standards.

In industrial settings, energy distribution systems must handle high voltages and currents, often under harsh environmental conditions. This requires robust design and advanced technology integration. For example, in a cement plant, the system must supply power to heavy-duty crushers, kilns, and conveyors without interruption. Similarly, in the oil and gas sector, energy distribution must support critical safety systems and continuous process operations.

Key components of energy distribution systems include:

Transformers: Step voltage levels up or down to match equipment requirements.

Switchgear: Control and protect electrical circuits.

Busbars: Conduct electricity within switchgear and distribution panels.

Cables and Conductors: Transmit power across distances.

Protection Devices: Circuit breakers and relays to prevent faults.

By integrating these components effectively, industries can achieve reliable power delivery, minimize energy losses, and enhance operational safety.

Key Components and Design Considerations of Energy Distribution Systems

Designing an energy distribution system for industrial applications requires a deep understanding of load characteristics, safety standards, and future scalability. Here are some critical design considerations:

Load Analysis and Demand Forecasting

Accurate load analysis helps determine the capacity and configuration of the distribution system. It involves assessing peak loads, diversity factors, and load growth projections. For instance, a sugar mill might experience seasonal load variations, which must be accounted for in system design.

System Configuration

Common configurations include radial, ring, and mesh networks. Each has its advantages:

Radial systems are simple and cost-effective but less reliable.

Ring systems offer better reliability by providing alternative power paths.

Mesh systems provide the highest reliability but are complex and expensive.

Choosing the right configuration depends on the criticality of the load and budget constraints.

Protection and Safety

Industrial environments demand stringent protection mechanisms. Protective relays, circuit breakers, and grounding systems must be carefully selected and coordinated to isolate faults quickly and prevent equipment damage or personnel hazards.

Energy Efficiency and Sustainability

Modern energy distribution systems incorporate energy-efficient transformers, smart meters, and automated controls. These technologies help reduce losses, monitor consumption in real-time, and support sustainability goals.

Integration with Automation and Industry 4.0

The future of energy distribution lies in smart grids and automation. Integrating sensors, IoT devices, and advanced analytics enables predictive maintenance, fault detection, and optimized energy management.

By focusing on these design principles, industries can build resilient and future-proof energy distribution systems that support growth and sustainability.

What is a Distributed Power System?

A distributed power system refers to a decentralized approach to energy generation and distribution. Instead of relying solely on a central power plant, distributed systems use multiple smaller generation sources located close to the point of consumption. These can include solar panels, wind turbines, microturbines, and energy storage units.

Advantages of Distributed Power Systems

Reduced Transmission Losses: Power is generated near the load, minimizing losses.

Enhanced Reliability: Multiple sources reduce the risk of total power failure.

Scalability: Systems can be expanded incrementally as demand grows.

Support for Renewable Energy: Facilitates integration of clean energy sources.

In industrial contexts, distributed power systems can provide backup power, reduce dependency on the grid, and improve energy security. For example, a metals processing plant might use onsite solar generation combined with battery storage to maintain operations during grid outages.

Challenges and Considerations

Complex Control Systems: Managing multiple generation sources requires sophisticated control and communication.

Initial Investment: Higher upfront costs compared to traditional centralized systems.

Regulatory Compliance: Must adhere to grid interconnection standards and safety regulations.

Despite these challenges, distributed power systems represent a forward-looking solution aligned with Industry 4.0 and sustainability objectives.

Implementing Reliable and Efficient Power Distribution Systems

To implement a reliable and efficient power distribution system solution, industries must adopt a holistic approach that combines engineering expertise, technology, and operational best practices.

Step 1: Comprehensive Site Assessment

Begin with a detailed assessment of existing infrastructure, load profiles, and future expansion plans. This helps identify bottlenecks and opportunities for improvement.

Step 2: Customized System Design

Leverage advanced simulation tools and industry standards to design a system tailored to your operational needs. Consider factors such as fault tolerance, energy efficiency, and automation integration.

Step 3: Quality Equipment Selection

Choose high-quality components from reputable manufacturers. Equipment reliability directly impacts system uptime and maintenance costs.

Step 4: Skilled Installation and Commissioning

Ensure installation is performed by certified professionals following strict safety protocols. Proper commissioning validates system performance and compliance.

Step 5: Ongoing Monitoring and Maintenance

Implement real-time monitoring systems to track performance and detect anomalies early. Scheduled maintenance prevents unexpected failures and extends equipment life.

Step 6: Continuous Improvement and Upgrades

Stay abreast of technological advancements and regulatory changes. Periodically review and upgrade your system to maintain optimal performance and sustainability.

By following these steps, industries can achieve a power distribution infrastructure that supports operational excellence and long-term growth.

Future Trends Shaping Energy Distribution Systems

The landscape of energy distribution is evolving rapidly, driven by technological innovation and sustainability imperatives. Here are some key trends to watch:

Smart Grids and Digitalization

Smart grids use digital communication and automation to optimize power flow, enhance reliability, and enable demand response. Integration with Industry 4.0 technologies allows predictive analytics and remote management.

Renewable Energy Integration

As industries adopt renewable energy sources, distribution systems must accommodate variable generation and storage. Hybrid systems combining solar, wind, and batteries are becoming common.

Energy Storage Solutions

Advanced battery technologies and other storage methods help balance supply and demand, improve power quality, and provide backup during outages.

Electrification and Decarbonization

Electrification of industrial processes and the push for carbon neutrality are driving upgrades in energy distribution infrastructure to handle increased loads and cleaner energy sources.

Cybersecurity

With increased digitalization, protecting energy distribution systems from cyber threats is paramount. Robust cybersecurity measures are essential to safeguard critical infrastructure.

Embracing these trends will position industries to meet future challenges while enhancing efficiency and sustainability.

Building a Resilient Energy Future Together

Understanding and optimizing energy distribution systems is a strategic imperative for industries aiming to enhance productivity, reduce costs, and achieve sustainability goals. By investing in robust design, advanced technology, and proactive management, you can build a resilient energy infrastructure that supports your operational needs today and adapts to tomorrow’s challenges.

At Industrial IT Solutions Pvt. Ltd., we are committed to partnering with you on this journey. Our expertise in turnkey automation, electrical, and mechanical solutions, combined with our focus on innovation and sustainability, empowers industries worldwide to thrive in a dynamic energy landscape.

Let’s work together to harness the full potential of your energy distribution systems and drive industrial excellence.

Comments